PRODUCTS' DETAILS

Products

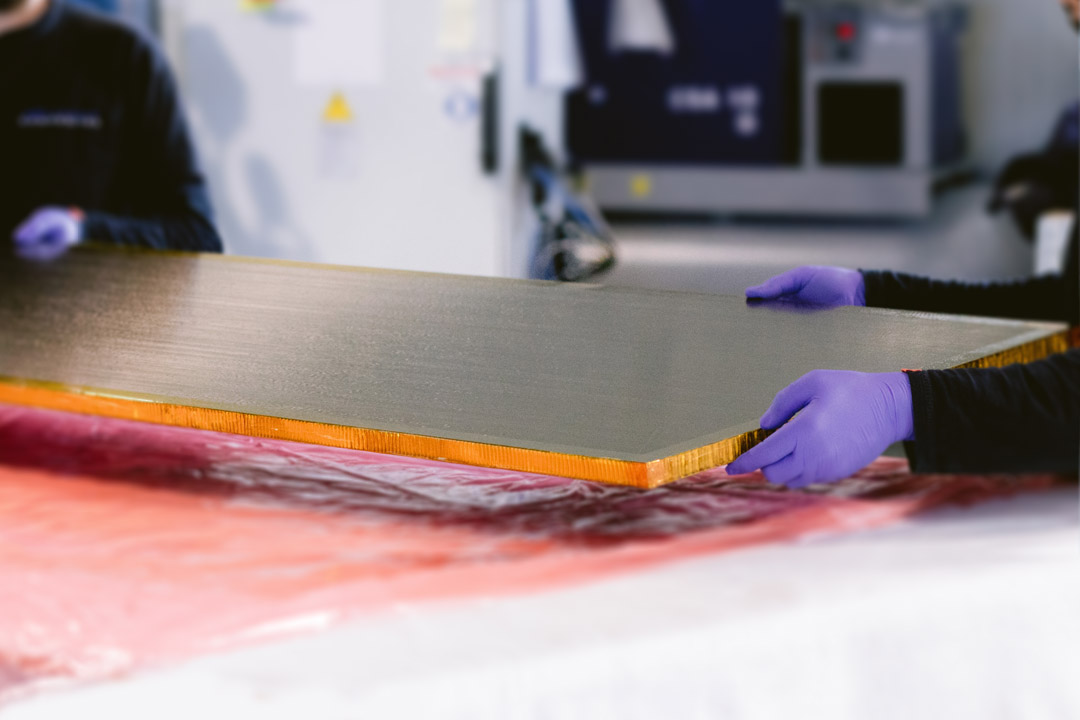

CFRP Sandwich Panels

Background Heritage: ESA Technology Development programmes (TRP, GSTP)

Description

Since 2012, Adamant Composites has been establishing capabilities and developing industrial know-how to produce CFRP sandwich panels for satellites structures and instruments. An autoclave production line is established capable of Built to Print producing sandwich panels up to 2 x 1 m. The processing of epoxy and cyanate ester prepregs has been demonstrated through ESA activities. Thanks to in house established engineering capabilities also Build to Spec option is offered.

Key Points

Structural Panels, Instruments, Thermal Panels, Small satellites

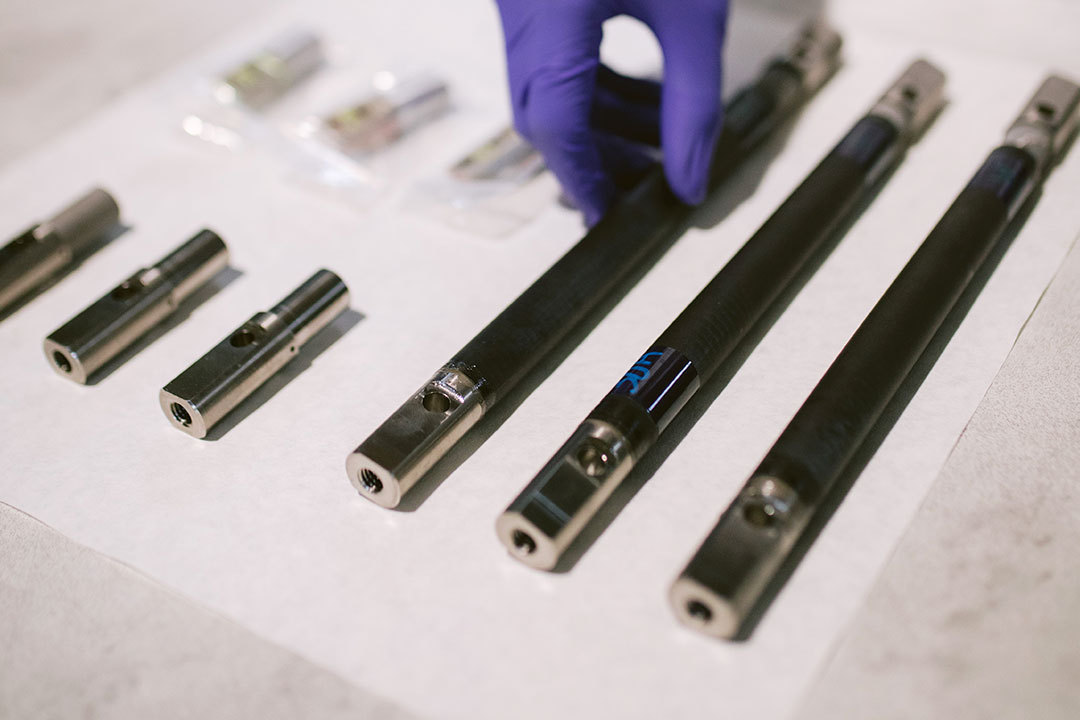

CFRP Struts

Background Heritage: ESA Technology Development programmes (CTP)

Description

Lightweight space structures often employ one dimensional elements that provide high stiffness and strength in preferred directions. Adamant Composites has developed and qualified its own struts for demanding high end applications such as deployable structures. The struts consist of CFRP tubes with engineered layup to meet the loading and operation specifications and customized metallic end fittings. Adhesive bonding for the assembly of the struts has been qualified for use in vacuum for a broad temperature range.

Key Points

Balanced axial and bending stiffness and strength, dimensionally stable, Tailored-made design

Lightweight Stable Large Deployable Truss

Background Heritage: ESA Technology Development programmes (CTP)

Description

Adamant Composites is developing a modular, scalable, ultra stable deployable/stowable truss system, configurable to deployment lengths of up to 20m. Possible applications include spaceborne telescopes, SAR earth observation spacecraft as well as deployable masts for antenna reflectors.

Currently, an Engineering Qualification model for a deployable truss of 12m in length, 3.9m in diameter is being developed and expected to undergo full scale testing within 2020.

A 1:1 scale breadboard of 3m in deployed length has already been successfully tested, demonstrating the functionality of the truss and its actuation module, and verified the stiffness, repeatability and stability of the design. The truss structure, actuation system and associated MGSE are designed in-house. Component and subsystem level testing to EQM level have been completed.

The 12m long model is stowable to a height less than 1m, including its motorization system. The truss stability and repeatability allow it to deploy consistently with a positioning error below 1mm. The system is designed to be capable to operate in orbit with a Stability Ratio of 10e-4 while its stiffness for a 1000kg payload is > 3Hz.

Key Points

Large Stable Deployable Truss, Modular High Stiffness Deployable Structure

Deployable Antenna for Small Satellites

Background Heritage: ESA Technology Development programmes (TRP, GSTP)

Description

Adamant Composites is currently developing a deployable X-band reflector antenna for small spacecraft with the target of TRL7 in 2022. The size of the S/C targeted is 1m cube while the diameter of the reflector is 1.5 to 2m, with a gain more than 40 dBi. The structural design employs lightweight CFRP elements while the RF design utilizes standard and novel reflective mesh technologies.

Key Points

Small spacecraft, science missions, communication antennas, SAR antennas

FXply™ nano-enabled prepregs for improved CFRP structures

Background Heritage: ESA Technology Development programmes (TRP, GSTP)

Description

FXply™ Prepregs are commercial prepregs modified with tailored nano-formulations towards specific performance characteristics. FXply™ Prepreg Technology enables conventional prepregs to deliver additional functionalities such as toughness, electrical conductivity, thermal conductivity. FXply™ Prepregs products are seamlessly integrated into existing production processes. Our R2R production line can meet the demand of industrial project volumes. Standard FXply™ Prepregs products are available and customized formulations can be also developed.

FXply™ Prepreg Technology has been demonstrated in both epoxy and cyanate ester prepreg products.

Key Points

Sandwich Panels, Electronic Enclosures, Grid-stiffened structures, Light-weight booms

FXbond™ nano-Enabled Adhesives

Background Heritage: ESA Technology Development programmes (TRP, GSTP)

Description

The FXbond™ Adhesives provide a balanced performance between structural, electrical and thermal properties. The FXbond™ Technology is based on proprietary material design know-how and in-house processing technology. A dedicated pilot production line is established to serve industrial needs. Standard FXbond™ Adhesives products are available and customized formulations can be developed.

Materials: Epoxy, Silicone

Product forms: Liquid paste, film

Key Points

Grounding, Thermal Interface & Bonding, Potting